Establishing High Current on a Calcium Target

Steps For Re-Establishing after a Down

This page contains instructions for restoring beam on a calcium target for situations where we have been down for an extended time (i.e., 1 shift or longer). Instructions are numbered in order of steps shifters should take in order to safely return to production configuration. Note that not all steps may be applicable given each individual situation, and shifters should either consult with experts or exercise discretion when following this guide.

0. Reclaim DAQ from Hall C

This applies only if Hall C has been running the parity DAQ while we are down. This usually happens if hall C runs for an extended period of time but hall A does not.

- Contact Hall C, ask them to stop the current parity run, and kcoda on the DAQ.

- Once we have confirmed this is done, open CODA on adaq1 in the first workspace.

- Once open look for the PREX Analyzer Control Tool window. You should have controls for the feedback, the realtime analyzer, and for beam modulation. If any one of those does not appear on the window, consult the expert shift worker.

- Enable feedback by clicking "Launch Feedback RunForever"

- Enable our realtime analyzer by clicking "Launch Realtime RunForever"

- Start a run, even if there is no beam or we are not on the calcium target.

- Bear in mind charge feedback will not function until the current in hall A is ramped up to 150 uA. Charge feedback will run in the background but with low or no beam, it will have no effect.

- If you're concerned about charge feedback you can open the feedback log to see if the information is updating. Also in a LivePlot window you could load the configuration CREX/Feedback-Monitor. If charge asymmetry values are changing AND the hall in question is ramped up, charge feedback is working.

1. Harp Scans

MCC should conduct harp scans as part of their normal restoration procedure from any long down. However, if they forget or if you can't find the results follow this procedure:

- Move the target to Carbon-1%.

- Call MCC ask for harp scans on 1H04A and 1H04B, with no raster.

- Observe on the raster scope that raster has disappeared.

- Doing both harp scans will take a few minutes. Keep checking the ELOG or the HALOG for posted results. The results should be in an entry with "Harp Fitter Tool" and the name of the harp in question in the title.

- More experienced shifters can open the Harp Fitter Tool directly from JMenu under System Expert > Harps > Harp Fitter Tool. Open the drop down menu from Harp Selection and choose Hall A > IHA1H04A or IHA104B depending on which you're interested in. The file name will contain the date and time of the scan being fit. If the date and time are current (i.e., after you requested a scan) then you can use these results. Otherwise continue to wait and check the ELOG.

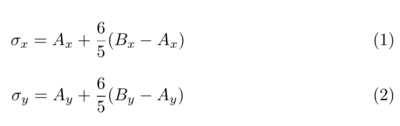

- Once you have harp fits either from the ELOG or the Fitter Tool, look for the "X Sigma" and "Y Sigma" fields near the bottom. Record the values of X and Y for 4A and 4B. Use the following formulae to calculate the projected spot size on target in mm:

- Both σ in x and y should be greater than 0.1 mm when projected on target. If not, see the section below on how to re-tune the optics to match design. Repeat the process as necessary until our spot size is acceptable.

2. Raster Check

Once our spot size is established we need to verify the size of the raster on target. We normally run with a 2 mm x 2 mm raster on target which does not always correspond nicely to MCC's units. Note that the raster settings on the board may not be correct once we do this check especially if the currents in our moller quads have changed since the last production!

- Once target motion is masked, move the target to Carbon Hole.

- While the target is moving, open the Raster desktop on hacweb7, and make sure the raster control screen is open.

- If it's not open, you can open it yourself from JMenu under Beam Setup > Hall A > Magnets > Raster.

- On the high voltage GUIs turn on the S0 and S3 scintillators in both arms.

- Find the HVgui numbered rpi8. Enable voltages on channels L0.0, L0.1, L0.2, L0.3, and L0.4.

- Do the same for the HVgui numbered rpi4. This turns on S0 and S3 in both arms.

- Once the target is finished moving call MCC and ask for 0.3 μA of 4 x 4 rastered beam (use the whiteboard setpoints). Ask that they change the target lock to the carbon hole center position (should also be on whiteboard).

- Ask also that MCC send tune beam first to allow the target lock to establish itself.

- Open the RHRS and LHRS CODAs on adaq1. They should be on the second workspace. These are the CODA windows from adaq2 and adaq3.

- Once the positions are settled and CW is established, begin taking runs on both the RHRS and LHRS CODAs.

- Once both DAQs have >50k events, open two terminal windows, and ssh into a-onl on any of the aonl machines. In one terminal run

spot_L <LHRS run #>, and in the other runspot_R <RHRS run #>.- If either of the spot++ runs fail, just run them a few more times until they succeed.

- Each of the spot++ runs will generate a PDF with plots. At the end of the first page there will be a 2D histogram with the reconstructed raster and target. You should see a rectangular raster with a hole roughly in the center. The hole is the carbon hole which has a 2 mm diameter.

- Visually inspect the plot. Is the hole width and height of the hole roughly half the width and height of the raster? If yes, then proceed. If not, then decide which dimension is too large or too small, and call MCC to adjust the raster setpoints accordingly. Note that the setpoints on the raster control screen are written in MCC's units, and you will have to adjust those to get the raster you want. Stop the current HRS runs and once you confirm the raster is changed, start new ones. Repeat the spot++ analysis, and inspect the raster again.

- If you don't feel confident in your raster size estimate, this section below might be helpful to get a higher-resolution picture of the carbon-hole.

- Once you have found a raster setting that appears to be 4 mm x 4 mm on target then take the current raster setpoints in MCC units and divide them both by two. These are the new setpoints for the 2 x 2 raster. If you did not need to adjust the raster from its initial setting, then the setpoints can remain unchanged.

- Do not run a 2 x 2 raster on the Carbon Hole, this will not teach you anything.

3. Go to 150 uA on Carbon 1%

- Check the LHRS and RHRS high voltages on rpi8 and rpi4. In both GUIs verify that the channels L0.0, L0.1, L0.2, L0.3, and L0.4 are all OFF. If you had just performed a raster check this is the time to turn the voltages for those scintillators off.

- Move the carbon 1% target in.

- Call MCC and ask for beam with the 2x2 raster, and the target lock positions to the calcium center position as written on the whiteboard. Ask that MCC send tune beam first in order to allow the target locks to readjust and settle to their new positions. Also ask MCC to set their ion chamber trip points to the carbon-1% 150μA levels.

- Setting ion chamber limits even for carbon targets is good practice, as it will be necessary for Ca48 running. We may adjust the Ca48 levels as we run further, so check near hacweb7 for postings on that.

- For carbon-1% we've found that the following values work without tripping excessively:

| Ion Chamber Name | Ion Chamber Variable | Trip Point for 150 μA |

|---|---|---|

| Compton | IIC1P03 | 2000 |

| Moller | IIC1H00 | 10500 |

| Target Main | IIC1H04A | 12500 |

| Target Secondary | IIC1H04B | 3000 |

| Target US | IIC1H05 | 6800 |

| Dump Right | IIC1H07A | 20876 |

| Dump Left | IIC1H07B | 20561 |

- Once you observe the BPM4A and BPM4E positions settle to the correct positions, call MCC and ask for CW beam, and ramp up to 150 μA.

- If the target has not seen beam for more than a shift then when you first ramp up CW on the target you will see the vacuum pressure on the target begin to elevate. This is normal, especially when you ramp up to 150 μA in one go. Keep an eye on the target ladder temperatures, just to be safe.

4. Ramp up to 150 uA on Ca48

- Once we have a couple minutes on carbon-1% with stable beam in the correct positions, ask to move to the Ca48.

- While the target is moving visually confirm that all settings are still correct:

- Visually check the raster scope still looks like it's in a 2x2 settings.

- Verify the raster currents from the JMenu raster GUI match the settings either on the whiteboard, or what was decided on by raster check.

- Ensure that main detector and AT high voltages are on, and that S0, S3 and VDC high voltages are off.

- Ensure SAM high voltages are on.

- Verify that all spectrometer magnet currents match posted setpoints.

- Once all is verified, call MCC and set the ion chamber trip points to the Ca48 150 μA production levels. These should be posted somewhere near the hacweb7 computer. These set points are subject to change, so confer with expert shift worker to verify the correct trip points.

- Once ion chamber setpoints are confirmed, ask to ramp up to 150 μA with raster and calcium target positions.

- Again, target vacuum spikes while ramping up current are normal when coming back from a long down. Monitor the vacuum to make sure the vacuum begins decreasing after a minute or two. Also monitor temperature alarms.

5. Miscellanea

Some subsystems such as beam modulation and compton will require additional recommissioning after a beam down. These activities are expert-driven and shifters need not concern themselves with performing them. If experts are present and performing their tests, then shifters should expect the experts to communicate clearly what they generally plan to do, and how it will affect the shifters' work.

Notes

Good logging practices

It's not written in any of the previous steps, but shifters are expected to record on the HALOG every configuration change they make to the experiment. This include, but may not be limited to:

- Target changes

- Turning on/off high voltages

- Raster size changes

- Plots made using the

raster_check.Cmacro - Changes to the realtime analyzer or any CODA configuration

Shifters are expected to make regular HALOG posts about experiment status as well. Don't be shy about using the HALOG, it's a tool all of us in the collaboration use.

What to do if spot size on target is unacceptable

Sometimes when coming back from a long down, especially one in which the injector orbit was tweaked, we find that our spot size is too small to safely run on target. If this is the case, then call MCC and ask them to run harp scans sequentially on the 1H00, 1C05, 1E01, 1L03, or 1L10 harps. These harps should indicate where the deviation from being "on design" should actually be, and will aid in instructing ops how to retune our spot size.

More raster check detail

If you've performed a raster check but are unsure of the size of the raster relative to the carbon hole, there is a macro you can use to help make it more clear. This method works best when you have at least 200000 events in each arm's run.

- Open two terminal windows

- In each window login in a-onl using

ssh -Y a-onl@aonl3- In the first window re-run spot++ ONLY if there is no other instance of spot running. Use

spot_L <LHRS run #> 200000. - In the second window, run spot_R <RHRS run #> 200000

- Upload the resulting plots to the logbook ONLY IF you haven't done so for these runs already.

- In the first window re-run spot++ ONLY if there is no other instance of spot running. Use

- Once one or both spots are finished in one of the windows do

cd ~/ajzec/raster_size_check/ - Run the macro named

raster_check.Cin the current directory with arguments for left or right HRS run, and the run number.- If you want to look at a LHRS run do

root -l rasterCheck.C'(1, <LHRS run #>)' - To look at a RHRS run do

root -l rasterCheck.C'(0, <RHRS run #>)'

- If you want to look at a LHRS run do

- Assuming the run rootfiles exist, this macro will give a higher resolution version of the same raster and hole plot you saw earlier. From here you can attempt to make a geometrical judgment of how large the raster size is.

- If you're still unsure about raster size, there is one more way to use this macro to estimate size. From the 2D plot generated in the previous steps, estimate the value on x-axis representing the hole's left edge and its right edge. Do the same on the y-axis for the hole's lower and upper edges. You should have four "bounding box limits" for the hole. Record them.

- Quit root. Re-run the macro with the four values you obtained. Run it with

root -l raster_check.C'(<1 for LHRS, 0 for RHRS>, <LHRS or RHRS run #>, <left edge limit>, <right edge limit>, <lower edge limit>, <upper edge limit>)'. - This will generate two 1D histograms, acting as projections of the x and y axes on the previous plot. The blue line applies no cut to the data, the green and red lines apply fiducial cuts to the hole to try and eliminate "noise" from events not originating from the hole directly.

- From these two plots you can estimate the hole width and height numerically and compare it to the size of the full raster. Is the size you measure for the whole close to half that of the full raster for both x and y? If so, then the raster is correct.

- If one dimension is not, then determine if the raster is too large or too small. Adjust set points accordingly.

- You can generate these two plots for both LHRS and RHRS runs, and see if they visually and numerically agree roughly.