Beam and Hall checks

From PREX Wiki

Revision as of 14:26, 27 June 2019 by Caryn Palatchi (talk | contribs)

In the process of editing and updating this page. Please contact Juliette Mammei crowder@jlab.org with questions or suggestions.

PREX Main<< Information for Shift Takers << Shift Leader << Shift Checklist

Alarm Handler

- VESDA System OK? (see Figure 8)

- VESDA is the smoke/fire detection and alarm system

- Check the Hall A VESDA Console on the wall behind the door

- Every light should be green and in the minimum lowest alert setting.

- Is alarm handler running on hacweb7?

- On hacweb 7, you should see a window in the upper right corner of the screen

- Look first in the "Alarm Handler" desktop to see if it is there

- Check all the windows if not

- If not open, see Alarm Handler

- On hacweb 7, you should see a window in the upper right corner of the screen

- Is the volume up on hacweb7? (both hardware and software)

- Go to Alarm Hall A Alarm Handler -> Setup -> Test Beep Sound

Beamline

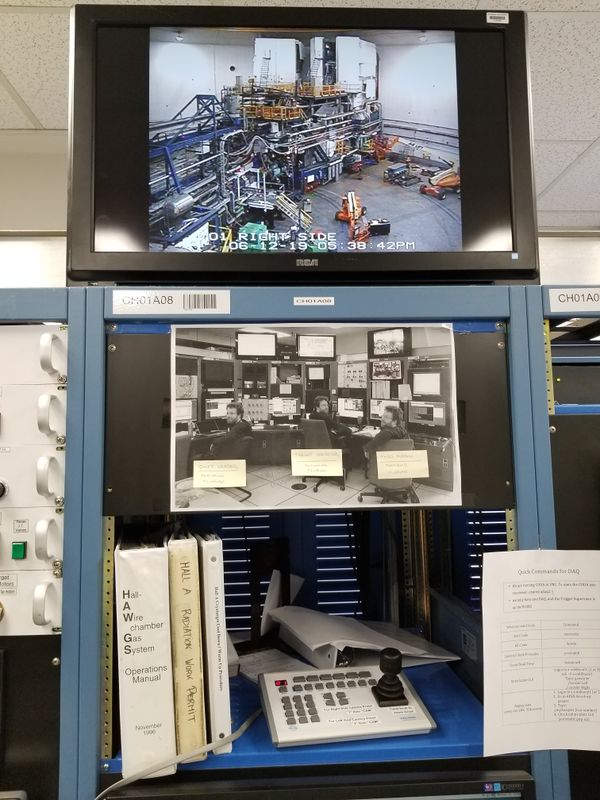

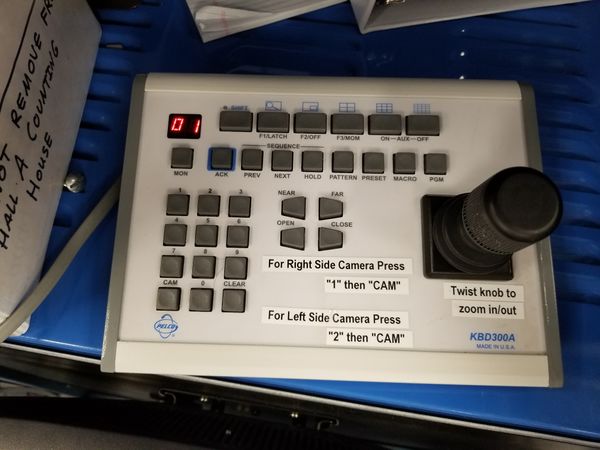

- Visual Hall Inspection OK? (see Figure 9)

- Make sure to move the camera around and zoom in (See Figure 10)

- when complete, zoom all the way back out

- Beam Energy (MeV) (see Figure 2)

- Beam Current (µA)

- Current Target (45 degree ladder/90 degree ladder)

- See Target GUI on Target computer

- Or JMenu -> Search for Target GUI -> "Hall A Target Lifter" and it has the same information (as well as raster and other useful information)

- Are the Hall A Target position slow locks functioning? - Should be locked during Parity Production

- JMenu -> Search for Orbit Lock -> Select "Orbit Locks Normal View"

- If HallATGT is Green and Lock Status = Running then the slow locks are enabled

- Beam Position Monitor (BPM) X/Y (mm) A

- Beam Position Monitor (BPM) X/Y (mm) E (Called BPM B in Hall A Tools)

- Downstream raster (labelled B or 2, US raster is not in use) on?

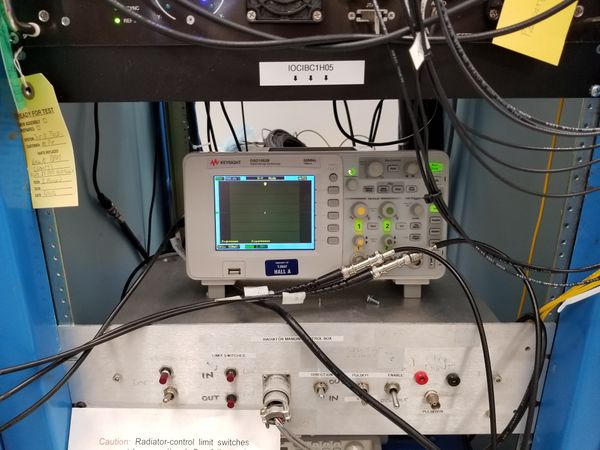

- Check the Oscilloscope in Counting House Middle Room: Yes/No

- when raster is off, looks like Figure 3

- when raster is on, something like halog 3654466

- Raster size (x vs. y in mm)?

- You can also check with the JMenu -> Hall A Fast Raster screen

- Fast feedback (FFB) on? Yes/No - should be on during Parity Production

- The easiest check is to look at the FFB information in bottom left corner of Hall A General Tools

- An additional way to check whether the FFB is on or off:

- in a terminal window, type JMenu

- search for "fast"

- Choose "Fast Feedback Control" (see Figure 5, which shows the upper left corner when FFB is OFF)

- The status is indicated by the button that is depressed (OFF and RUN in the figure)

- Do not use any of the Hall A Fast Feedback Control menus other than the "Fast Feedback Control" one. The screen should be small and have Hall A and C on it. You should NOT be able to edit any of the parameters.

- FFB should be ON during normal production running!

- However, FFB will be paused during beam modulation

- If BPMs are saturated or for FFB troubleshooting see: FFB troubleshooting

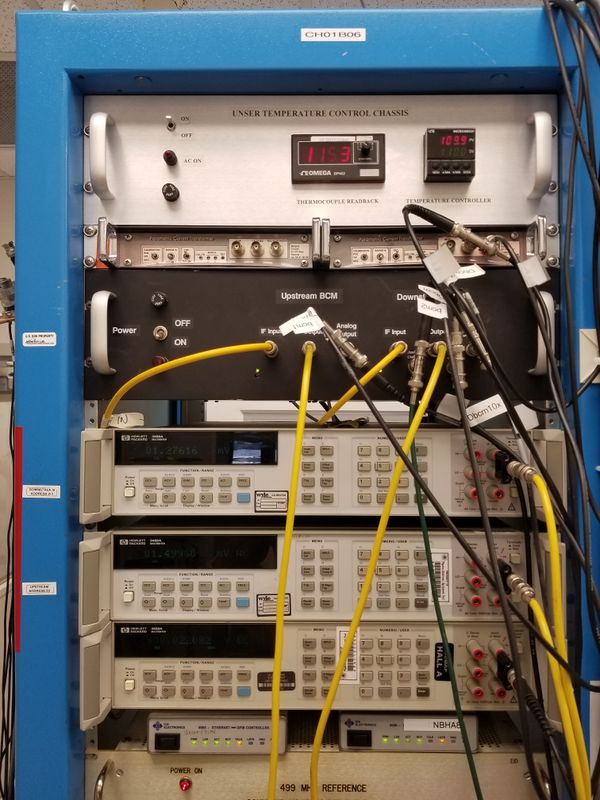

- BCM temperature (K) (PV, PS, Thermocouple)

- These temperature readbacks are located in the middle DAQ room, in rack CH0B06 (far left) at the very top (see Figure 4)

- If these differ by +/-.5 from (110.0, 110.0, 115.0) (Fahrenheit) contact RC and halog

- It is important that these temperatures stay stable within 0.5 Fahrenheit or else the BCM current readout will become uncalibrated

- Accelerator Arc Beam Energy NMR locked?

- Go to "Energy Lock GUI" from JMenu -> Applications section -> "Energy Locks"

- Verify if the box locked is ON/OFF - should be on during Parity Production

- If the 3 "OR", "1A", and "2A" lights are green then the energy is locked

Hall Status

- Are the Compton Background Rates sufficiently low (<10kHz)?

- JMenu -> Plots -> MyaPlot -> Right Click and Load a Configuration -> Select PREX in Directories -> Compton Background Rates -> Ok Move to Now

- If you see anything above 10kHz in any of the strip charts, this is bad, and the Compton Expert on shift should be notified

- Is the Compton DAQ running? (It should be during Parity Production)

- Ask the Compton expert on shift

- Is the Compton Photon Detector PMT High Voltage on? (It should be during Parity Production)

- Look at the Low Voltage power supply, it is at the bottom of the electronics rack CH01B00 in the middle DAQ Counting House room.

- It is a small box with a banana plug -> BNC cable plugged into it

- The Voltage should read approximately 5.3 Volts

- Is the Moller Polarimeter within operational temperature limits? See Figure 11 for reference or Simona's elog entry

- The screen can be obt ained through: NewTools -> JMenu -> "Moller Polarimeter Temperature Monitor" -> Hall A Moller Temperature

- The optimal points are: Cryocooler (T1) ~ 3K, Magnet (T2) ~3K, Magnet Lead #1 ~40K, Magnet Lead #2 ~ 40K

- If something happens for the Moller Polarimeter, Call Simona

- Septum current (A) and polarity? Matches whiteboard set-point?

- JMenu -> Search for Big Bite Septum or Hall A Septum

- Before adjusting septum please read and sign the septum OSP document (in the yellow OSP folder)

Gasses

- Pressures (see Figure 6)

- Argon pressure (psi)

- Ethane pressure (psi)

- CO2 pressure (psi)

Next in checklist >> Parity Checks